I am incapable of being dishonest. Yes I am "busting" the ...well... of the designers of the kit. I can't ignore the weak points even though I think the overall design is very, very good.

Also, this may be the last post where I recommend ways of building stuff. My ways are not the only ways.. but for me they tend on being the best. If I was fully pro in assembly, I'd have a reflow oven, hot air rework guns and pre-heaters, stencils made for these boards, etc. Since we are hobbyists we have to make do with the tools we can afford. My rantings of how to build things are what works best for me since I've been doing home electronic construction for almost 30 years. (and yes I'm only 41.)

Honestly, the internal cable kit is a "do not buy" if you are contemplating the kit but have not sprung for it. I could have built the same thing out of my own scraps as opposed to some one else's in NO additional time. I actually had to for one cable---

Worse yet, I get frustrated enough when I screw up my own parts when building. But when they come "pre-screwed up" I get even more frustrated. Hint for people kitting up parts: Samtec sells connectors that are cut to the right dimensions in reasonable quantities-- and they are a treat to deal with. By far the best vendor I've ever worked with. Snap-offs are okay, also. But cutoffs (at all and worse) done incorrectly are not. Also there are 0.100" connectors available that have crimp-on socket pins (known as Box Sockets) that make much cleaner connections that tack soldering to a PCB connector! Those crimp on pins can be soldered to if you don't have the tool.

Box Sockets can be redone if the pinout is off, no heat shrink is required.. the pins have mechanical support as opposed to being tack soldered, etc. I will likely redo my cables in this fashion at a later time.

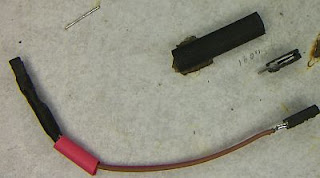

Anyway.. if you DO insist on cutting off PCB SIP sockets... PLEASE realize you MUST sacrifice a pin to do this. attempting to get, for example two 2-pin headers out of a 4-pin results in this:

The top two were like this from the kit. The one on the top right looked okay but did this as soon as I started to heat shrink. The bottom two are cutoffs that I did from my own scraps. Those are now on my RF cable.

To make the bottom two I eliminated (destroyed) a row in between on both connectors and filed it down (more than is shown in the picture).

When you go to build these cables, print out the first four pages and throw out the last three. I think George was trying to be clever with 23 pieces of heat shrink out of a 5" long piece and 13 out of a 4" piece but life is too short for this. As it is since we are tack soldering to PCB connectors it takes far too long to build these.. like hours when it should be minutes.

Get your heat shrink tubing kit out of your junk box. If you don't have one.. go to Harbor Freight and get their "Storehouse" kit of heat shrink. Cut pieces that fit and protect the connectors as needed. I think because the Softrock ends up looking like "Hydra the Leviathan" at the end.. the idea of marking pin one on every cable is a great one. I used watercolors from the kids to do this... when you screw one up you just wash it off.. and it seem durable enough since handling should be somewhat limited of the cables.

Here is me assembling the power cable:

I used some of the tubing with the kit on the two pin connectors since I could then shrink them over the connector with the better looking black stuff. It looks pretty decent actually for being made out of scraps.

The red paint on this one is the + side, pin 1. All other cables have dots of a different color.

Here is the RX audio cable being made a similar way:

The small vise (drill press vise from Harbor Freight) helps a lot when tack soldering these beasties.

Use two (oops, not included) 2-pin pin headers to test each cable as you'll be cross eyed by the time you are done following the diagram and you really should verify the cables are good this way. There are some combinations of errors that IMHO could possibly damage the Softrock or the DSP card or both. Bug it with a meter. Maybe a resistor lead would work instead of the pin header?

The same vise pictured above, of course, makes a dandy IDC connector crimper (recommended in the instructions) almost as good as the $100+ 3M tool. I was at home this week so I crimped my IDC cable (which luckily wasn't scraps.. it's the best piece in the kit) with this vice.

See.. now this looks professional. (But still use the 2-pin headers to test all of the pins on the cable.) But it's again odd that there is a swap going on (if it wasn't like this an old computer IDC cable could be used... huurumph). I'm starting to think that the machinations for fitting this and the Softrock into the cute little cube were not the best way to go with this. I mentioned earlier that I thought the regulator would fall off into the cube. Add these cables as well (probably not the IDC but the others certainly would on a vibe table). I'm really worried about this for you backpackers out there. I'd think about liberal tie-wrapping after everything works.

Anyway.. I am using a SR63ng instead of a Tony Parks Softrock 6.3 RXTX board. I am getting a TXPA (PAF) from George (if I don't insult him too badly with this post) which can mate with the sr63ng just like on a Softrock.

On the sr63.. there was a four pin socket for the I2C.. apparently this is how the MOBO did it? Anyway, instead of the three pin socket I made a four pin header for the cable (since it's tack soldered on anyway!).

On the TX Audio cable.. please tell me that the one extra header isn't to avoid having the 3.3V LDO on the Softrock to save a mA or two and $3?!? I bet it is. I put it on mine to be standard.. but it will be tie-wrapped off and I will leave on the LDO for the sr63ng as it's much cleaner this way.

Here are all of my color-coded pin 1 cables. For the RXAMP I labelled the ends with a Sharpie on the cable as well.

It is NOT a "Flying Spaghetti Monster!!!".. it's a sr63ng with all of the cabling to go to the SDR-Cube, if I ever get it finished. It even had color coded pin one dots. I think overall that is better than using red heat shrink to indicate pin 1 and blue to do the other pins. Shrinking over the connectors, by the way, provides a little extra mechanical support and looks a lot better.

Please, please, build it anyway you want though. My changes to the cabling are recommendations since they came out nice for a scrap build. They are not the only way of doing this. They are not the best. Box sockets would be the best.

I have to go back to work next week.. so I imagine progress and postings to this blog will slow somewhat. I need to actually take a break from this for a day or two.. it's starting to become not fun. It will be fun again after a short hiatus I am sure. I want to make one of the first cube-to-cube QSO's... anyone else building theirs up for 20 meters?

Until next time... happy building...

No comments:

Post a Comment